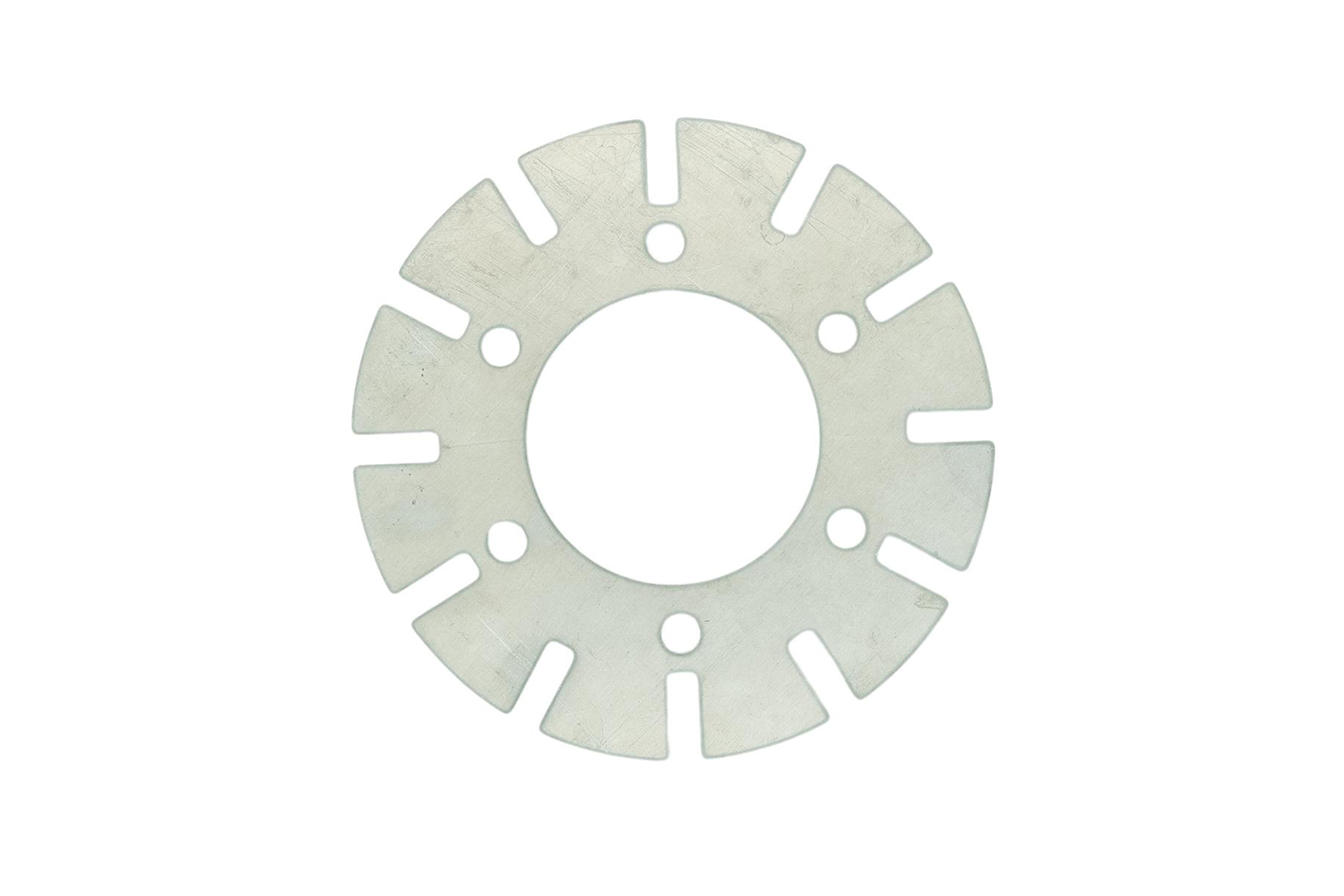

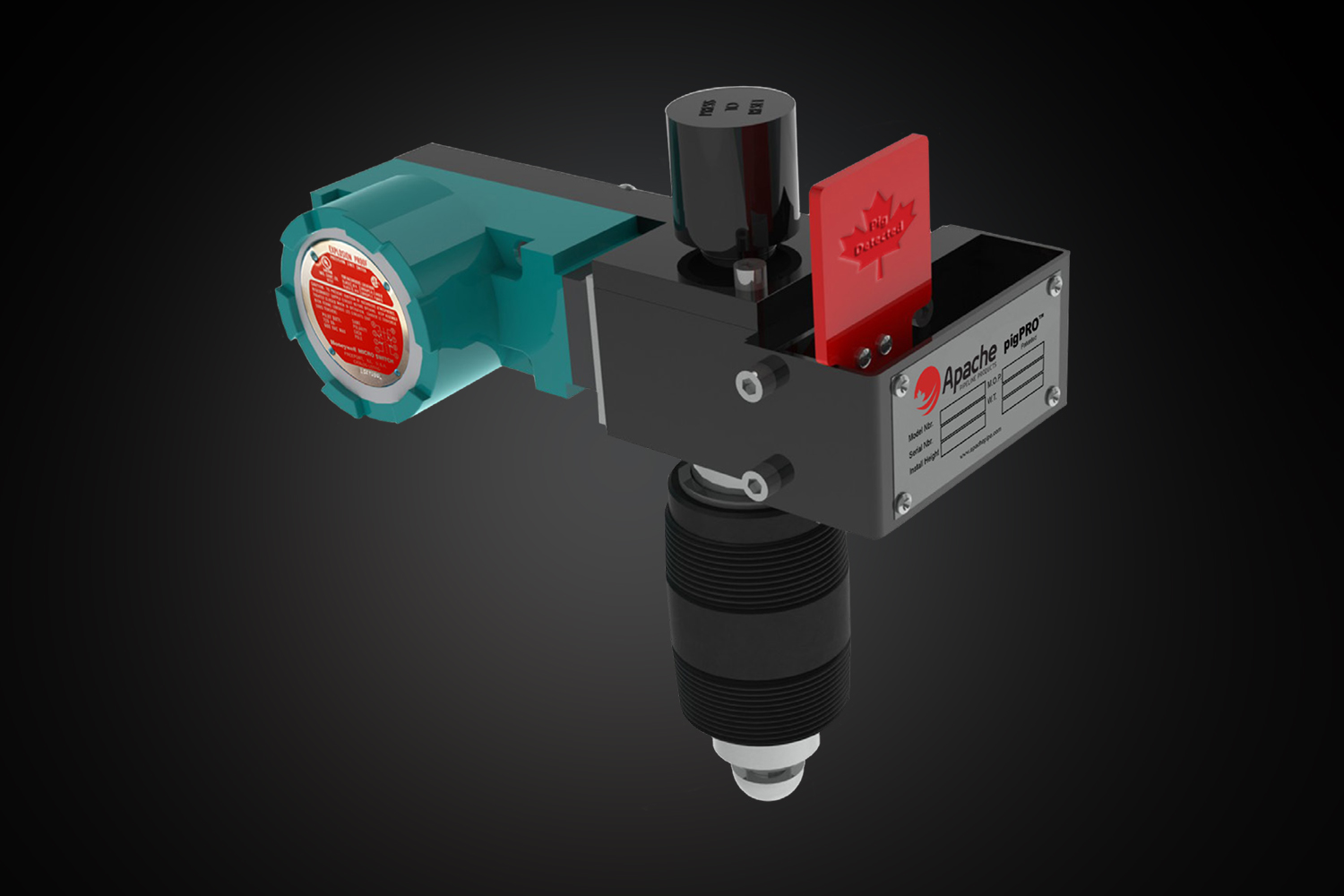

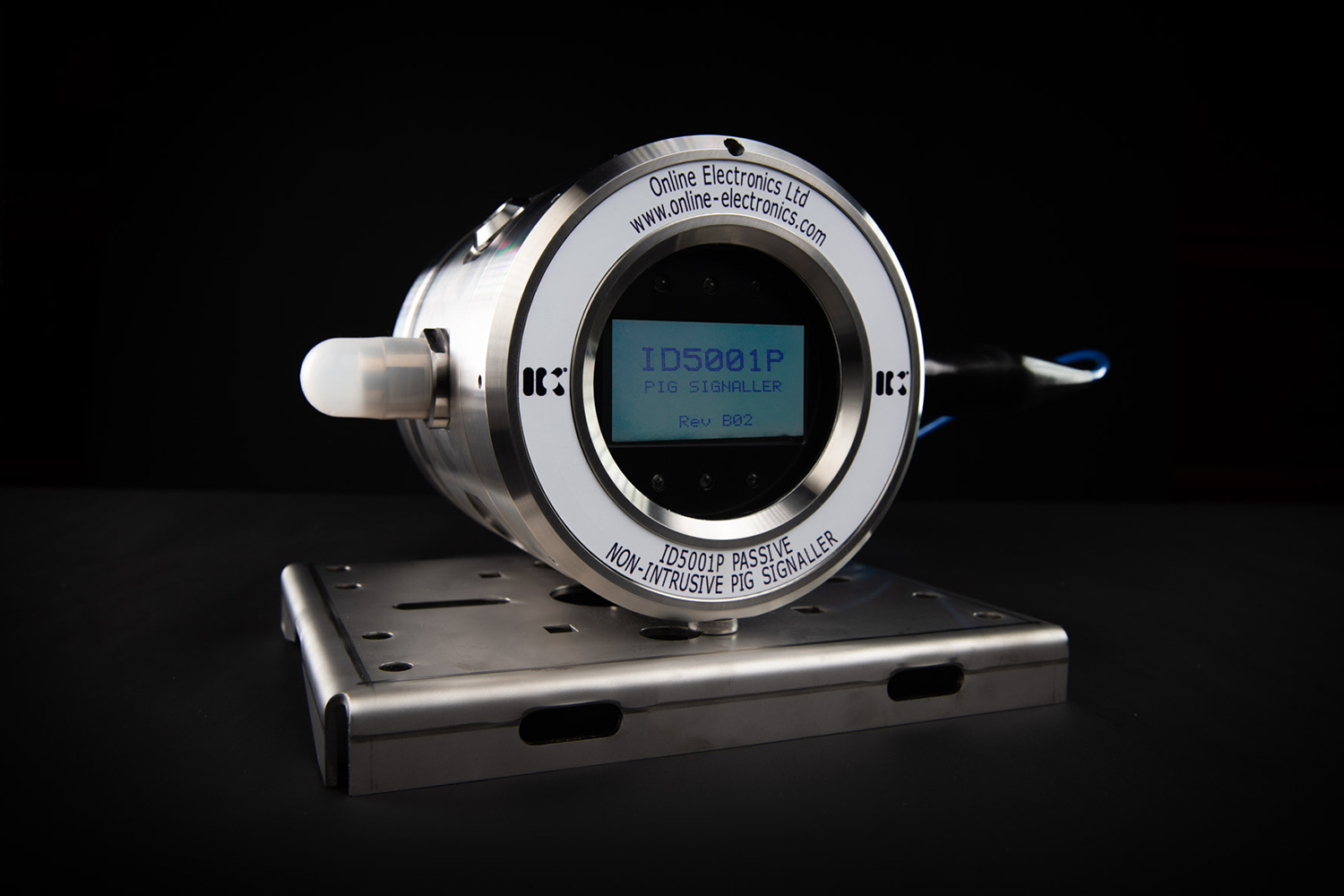

We offer an extensive inventory of Pigging Equipment and Accessories, for general cleaning programs, batching, product recovery, and corrosion mitigation and prevention. Our pipeline pigs are suitable for all pipeline applications including multi diameter, bi-directional, long distance, and high-risk offshore pipelines. Inline also offers 1.5D capable Active Speed Control Pigs for high velocity pipeline cleaning, as well as a complete suite of Pig Tracking Equipment, available for sale or rent, including a variety of Auto Tracking options, Transmitters, Receivers, Sensors and Geophones. Inline is also the exclusive U.S. distributor for the Apache pigPRO™Intrusive Pig Passage Indicator.